-

At Trust Engineering, we provide high-performance Asphalt Mixing Plants engineered to meet the demanding requirements of road construction and infrastructure projects. Our plants are built using robust carbon-steel structures and advanced control systems to ensure consistent, reliable, and efficient production even under the toughest operating conditions.

Design & Performance Features

Our asphalt mixing plants combine modern technology with high productivity, offering:

-

Superior homogeneous mixing, achieved through powerful, precisely-calibrated mixers that ensure optimal distribution of bitumen and aggregates.

-

Heavy-duty carbon-steel structures designed to withstand vibration and continuous operation with exceptional stability.

-

High-accuracy weighing systems that guarantee precise aggregate and bitumen proportions for optimal asphalt quality.

-

Automated control systems, enabling full monitoring and management of the production cycle through a modern, user-friendly interface.

Production Capacities

Trust Engineering offers a wide range of plant capacities to suit projects of all sizes—from compact units for local works to high-capacity plants for major infrastructure developments. Available configurations include:

Each solution is tailored to the project requirements and operational environment.

-

he Engineering Services Department is the cornerstone that supports all stages of industrial and engineering projects within Trust Engineering. This department combines deep technical expertise, analytical capabilities, and practical knowledge to ensure the delivery of comprehensive and effective solutions tailored to clients’ needs.

Scope of Engineering Services:

-

Preliminary engineering studies and project feasibility assessments.

-

Design of structural and mechanical plans in accordance with international standards.

-

Development of customized solutions for factories, production lines, and industrial facilities.

-

Engineering supervision of manufacturing, assembly, and installation phases.

-

Quality testing and verification of product compliance with global standards.

-

Providing technical and engineering consultancy to ensure optimal performance and operation.

This department aims to support clients in executing their projects efficiently and professionally—from planning to delivery—while emphasizing quality, safety, and sustainability.

-

At Trust Engineering, we provide advanced and specialized heat exchangers that are precisely designed and manufactured to meet the demands of critical industrial operations. Our heat exchangers are engineered to deliver optimal thermal performance with high reliability, even in the most challenging environments.

Types of Heat Exchangers

Our heat exchanger solutions include the following types:

Shell & Tube Heat Exchangers:

Consisting of an outer shell and internal tube bundles, this type is ideal for industrial processes involving high pressures and extreme temperatures.

Air-Cooled Heat Exchangers (Fin-Fan Coolers):

Utilize axial fans and finned tubes to efficiently cool liquids or gases, even in hot climates.

Plate Heat Exchangers:

A compact plate-based system used for efficient heat transfer in limited spaces, featuring a design that allows easy maintenance and cleaning.

-

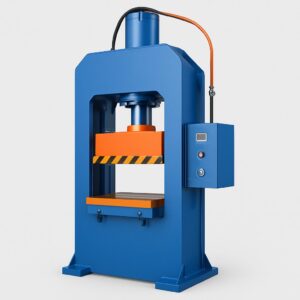

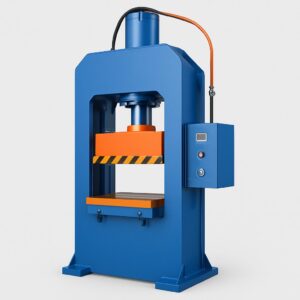

Hydraulic presses are high-capacity industrial machines that rely on hydraulic pressure to generate significant pressing force. They are used for metal forming, cutting, stamping, bending, and deep drawing. They feature high operational precision, excellent stability, and the ability to handle heavy loads while operating smoothly and quietly.

They are used in engineering factories, production lines, manufacturing workshops, and the automotive industry, providing high efficiency in converting raw materials into finished products with the highest quality standards.

-

At Trust Engineering, we design and manufacture fully integrated industrial production lines built to ensure maximum efficiency, precision, and continuous operation. Our solutions are tailored to meet the needs of diverse manufacturing sectors, providing clients with turnkey systems that support high productivity and long-term reliability.

End-to-End Production Line Solutions

We offer complete production line systems starting from engineering and concept design to fabrication, assembly, automation, and on-site commissioning. Each line is engineered to deliver seamless workflow, reduced downtime, and optimal output.

Our production lines can include:

-

Raw material feeding systems

-

Automated or semi-automated processing units

-

Conveyors, elevators, and material handling systems

-

Mixing, heating, or forming units (depending on industry)

-

Quality control and inspection stations

-

Filling, weighing, packaging, and palletizing modules

-

Central control systems, sensors, and PLC automation

-

At Trust Engineering, we specialize in the design, manufacturing, and installation of high-performance oil storage tanks and petroleum equipment that meet the rigorous demands of the oil, gas, and energy sectors. Our solutions are engineered to deliver maximum reliability, operational safety, and long-term durability, even in the most challenging industrial environments.

Advanced Engineering & Structural Design

Our tanks are designed using advanced engineering methodologies to ensure precision, efficiency, and compliance with international industrial standards. Trust Engineering offers a wide range of solutions, including:

-

Atmospheric Storage Tanks

Designed for stable performance under varying temperature and pressure conditions. Available with cone roofs, dome roofs, and customized configurations.

-

Pressure Vessels

Built to handle high-pressure operating environments, ideal for critical oil and gas processing applications.

-

Fuel Storage Tanks & Dispensing Systems

Equipped with loading and unloading lines, safety valves, and protection systems designed to prevent leaks and ensure safe fuel handling.

-

Trust Engineering specializes in delivering advanced steel structure solutions designed for industrial, commercial, and large-scale construction projects. With strong engineering expertise and high-capacity manufacturing facilities, we provide comprehensive steel structure services that ensure durability, precision, and long-term performance.

Comprehensive Engineering Solutions

Our steel structures are developed through an end-to-end workflow that includes:

design analysis, structural calculations, detailed shop drawings, high-quality fabrication, surface treatment, transportation, and on-site installation.

We manufacture a wide range of steel structures, including:

- Industrial plant buildings and production halls

- Warehouses and storage facilities

- Industrial and agricultural hangars

- Steel bridges and crossing structures

- Multi-storey steel buildings

- Towers, platforms, and heavy-duty support frames

- Custom steel structures for machinery and production lines